Multi core wire stripping and beating machine automatic wire

trimming and smoothing wire stripping and beating end machine

Automatic wire trimming, straightening multi-core wires, with

automatic straightening function, neat arrangement, accurate

position and high repeated positioning accuracy. For general

twisted pair core wires, it also has good straightening effect,

which can reduce stations, optimize process flow and reduce the

workload of operators. The equipment has high scalability and can

design functions that meet the production requirements according to

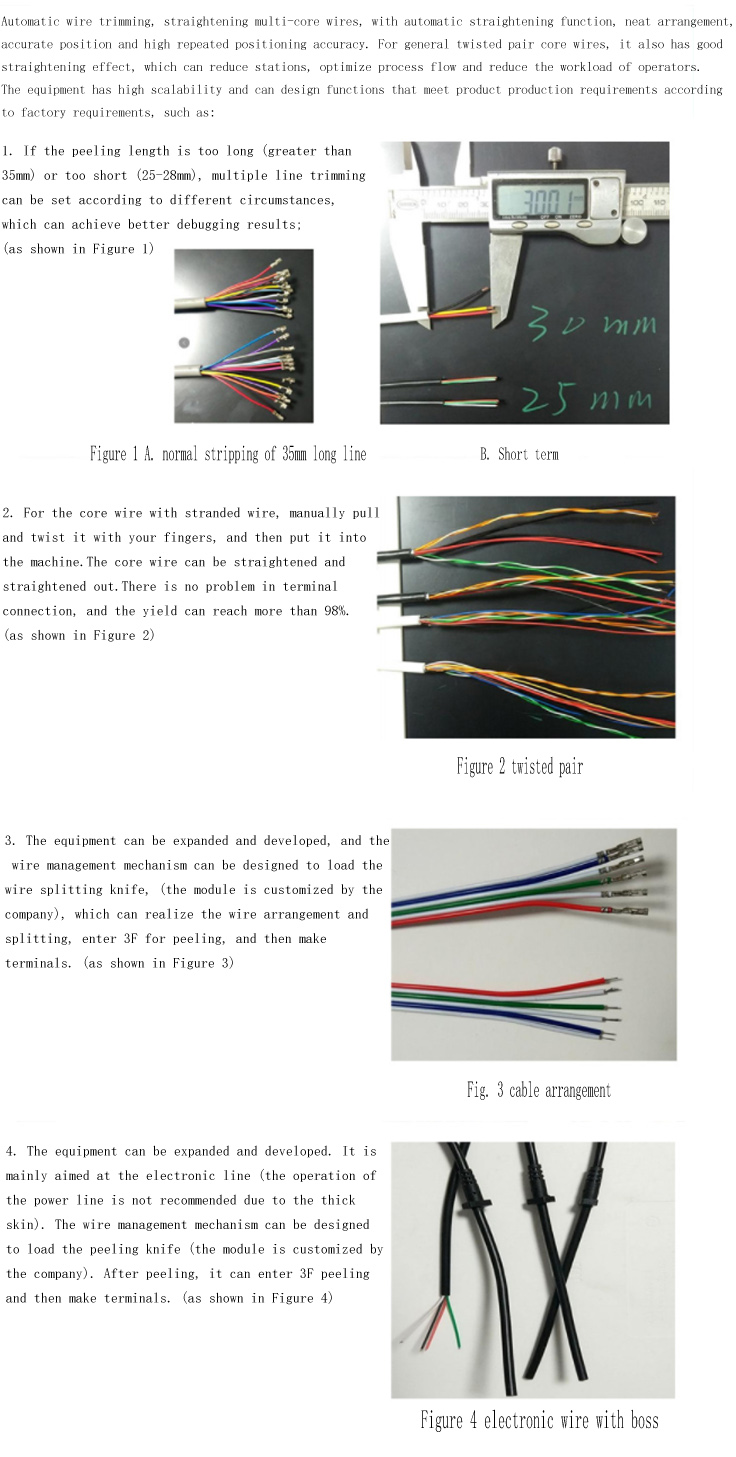

the factory requirements, for example: 1. If the peeling length is

too long (greater than 35mm) or too short (25-28mm) , multiple line

management can be set according to different circumstances, which

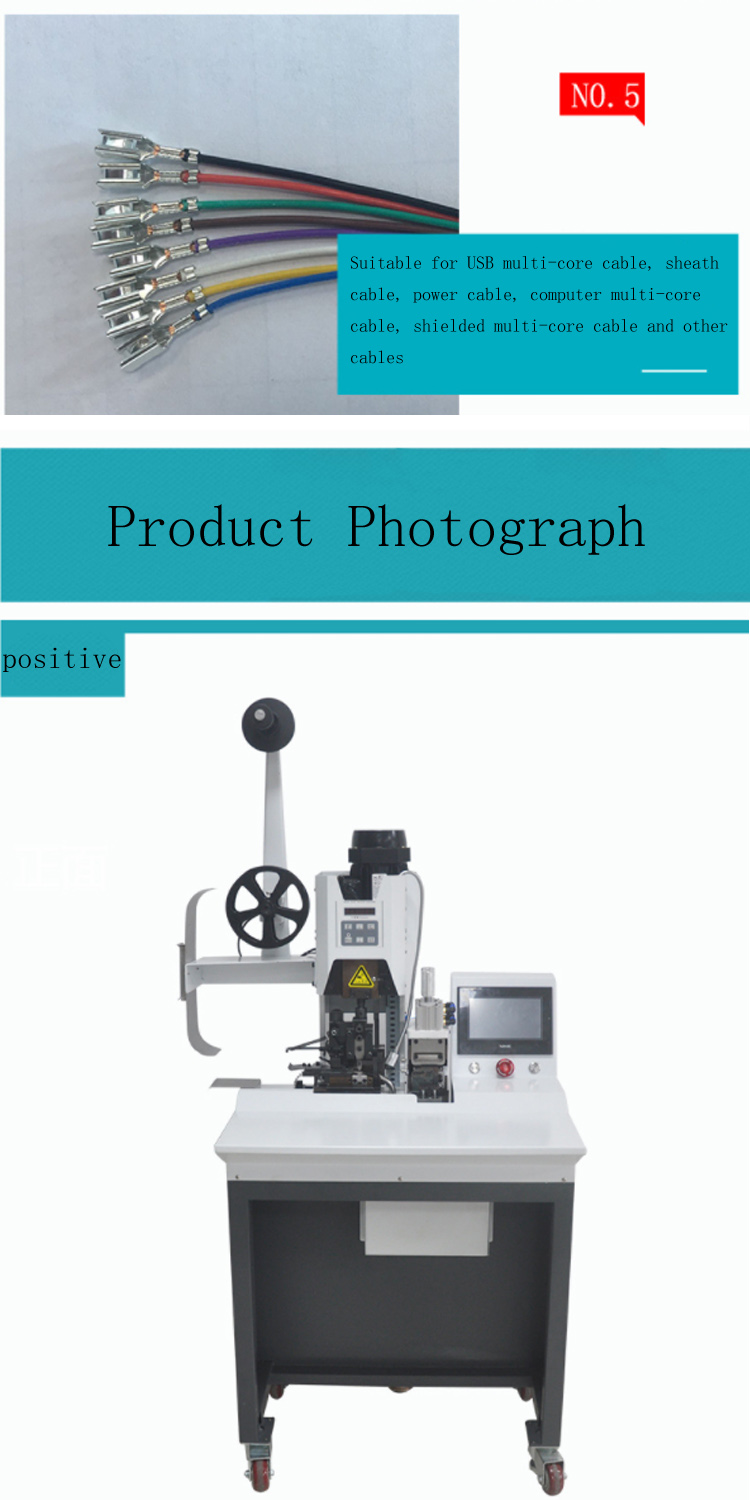

can achieve better debugging results; 2. The core wire with

stranded wire shall be manually opened and twisted with fingers,

and then put into the machine. The core wire can be straightened

and straightened,and there is no problem in terminal connection,

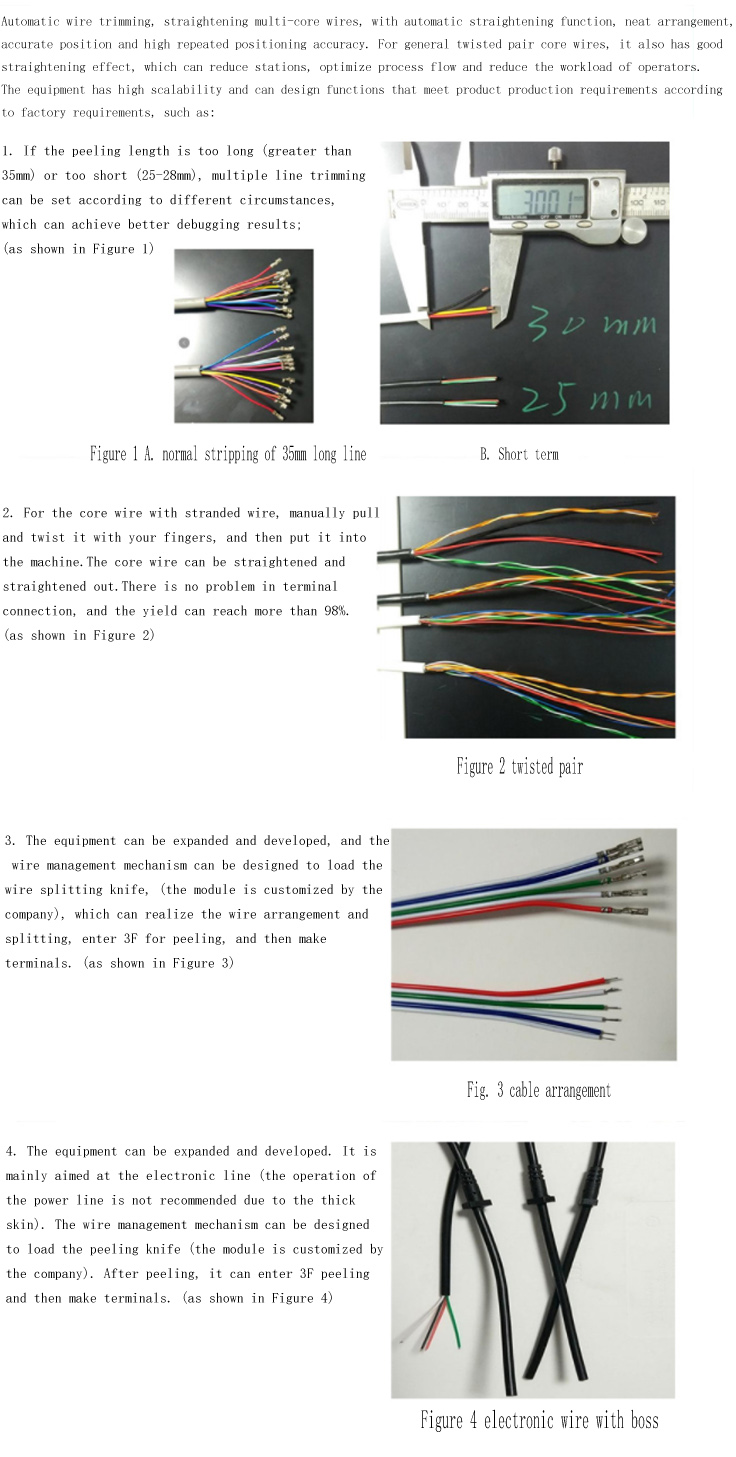

and the yield can reach more than 98%; 3. The equipment can be

expanded and developed, and the wire management mechanism can be

designed to load the wire splitting knife, (the module is

customized by the company), which can realize the stripping in 3F

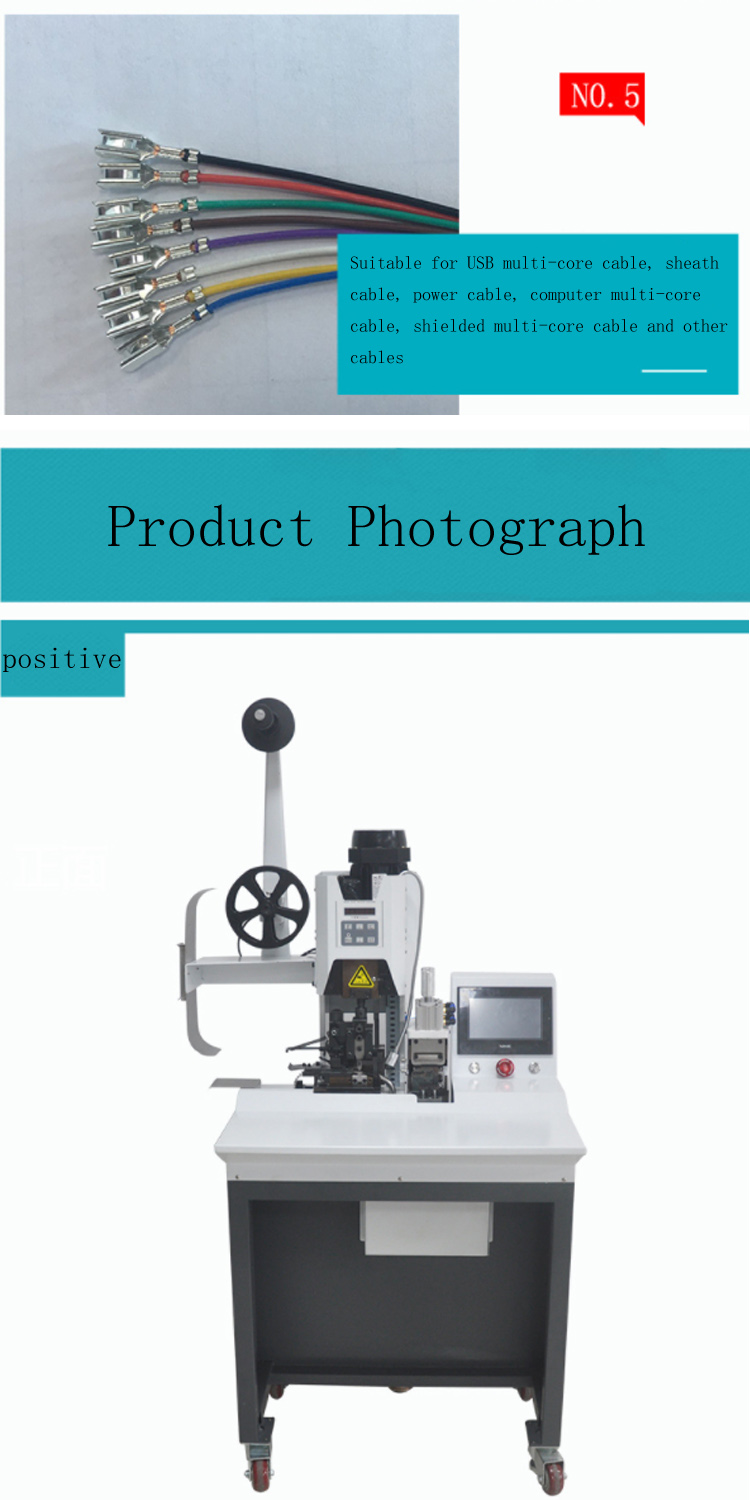

after wiring and branching, and then make terminals; 4. The

equipment can be expanded and developed. It is mainly aimed at the

electronic line (the operation of the power line is not recommended

due to the thick skin). The wire management mechanism can be

designed to load the peeling knife (the module is customized by the

company). After peeling, it can enter 3F peeling and then make

terminals.and the wire management mechanism can be designed to load

the wire splitting knife, (the module is customized by the

company), which can realize the stripping in 3F after wiring and

branching, and then make terminals; 4. The equipment can be

expanded and developed. It is mainly aimed at the electronic line

(the operation of the power line is not recommended due to the

thick skin). The wire management mechanism can be designed to load

the peeling knife (the module is customized by the company). After

peeling, it can enter 3F peeling and then make terminals.and the

wire management mechanism can be designed to load the wire

splitting knife, (the module is customized by the company), which

can realize the stripping in 3F after wiring and branching, and

then make terminals; 4. The equipment can be expanded and

developed. It is mainly aimed at the electronic line (the operation

of the power line is not recommended due to the thick skin). The

wire management mechanism can be designed to load the peeling knife

(the module is customized by the company). After peeling, it can

enter 3F peeling and then make terminals.It is mainly aimed at the

electronic line (the operation of the power line is not recommended

due to the thick skin). The wire management mechanism can be

designed to load the peeling knife (the module is customized by the

company). After peeling, it can enter 3F peeling and then make

terminals.It is mainly aimed at the electronic line (the operation

of the power line is not recommended due to the thick skin). The

wire management mechanism can be designed to load the peeling knife

(the module is customized by the company). After peeling, it can

enter 3F peeling and then make terminals.

Machine parameters| Machine name | Multi core wire peeling and end beating machine |

| Power Supply | 220V |

| capacity | 3600 / h (depending on wire) |

| Sheath stripping | The shortest peeling is 18mm (depending on the material) |

| Suitable wire diameter | 2-12p 18#awg-28# sheathed wire |

| Pressing capacity | 2.0T |

| Crimping stroke | 30MM |

| Applicable mould | OTP transverse mold and direct mold |

| Overall dimension | 650*500*1300MM |

| Shortest peeling | 20mm (depending on the wire) |

| Automatic waste cutting | have |

| Automatic waste paper collection | have |